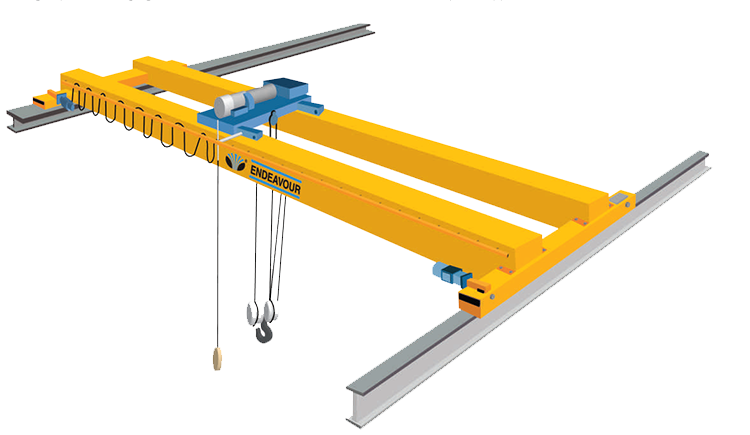

Our result-oriented way of working enabled us to be the top manufacturer and exporter of Double Girder Cranes. It constitutes as an advanced girder, end beam, trolley and electric parts in order to have an optimal efficiency in all aspects. Furthermore, we are offering a Double Girder Crane that is characterized by a simple assembling process; it is also robust and has an easy control model.

Lifting the Endeavor Double Girder Crane with high Performance& Functionality was assured by us while guaranteeing that blowing substances are saved in adequate safety factors in their them. So In accordance to duty classification as per IS-3177 and IS-4137…elsewhere- Single Girder Cranes are classified as one of the main types names available for EOT Cranes definitions. The cranes discussed are used largely in warehouses where they aid processing plants; they can also be found operating in factories and power stations. Such objects include materials at raw, finished or intermediate stage of production.

Features:

- High Efficiency

- Long Working Life

- Robust structure

- Less maintenance required

Installation:

Double Girder EOT Crane 10 MT

Double Girder EOT Crane 15 MT

Double Girder EOT Crane 3 MT

Applications:

Oil & Gas

Pharmaceutical

Logistics

Food Processing

Chemical

Cement

Packing

Mining

Frequently Asked Questions (FAQ):

A double girder EOT (Electric Overhead Traveling) crane is a type of overhead crane that features two parallel girders for supporting the bridge and trolley

- Increased lifting capacity

- Better stability and precision

- Suitable for heavy-duty applications

- Accommodates larger spans and lifting heights

- Allows for the installation of additional features like maintenance platforms and walkways.

- Manufacturing facilities

- Warehouses

- Ports and shipyards

- Accommodates larger spans and lifting heights Power plants

- Construction sites

- Steel mills and foundries

- Required lifting capacity

- Span and lifting height

- Duty cycle and operating conditions

- Available space for installation

- Power supply and control options

- Safety features and compliance with regulations

- Regular inspection of critical components

- Lubrication of moving parts

- Monitoring of electrical systems

- Prompt repair of any damages or faults

- Training for operators on safe usage and maintenance procedures

Yes, double girder EOT cranes can be tailored to specific requirements regarding capacity, span, lifting height, and operational features.

- Operator training and certification

- Overload protection systems

- Emergency stop buttons

- Limit switches to prevent collisions and over-travel

- Regular inspection and maintenance routines

- Clear communication between operators and ground personnel.