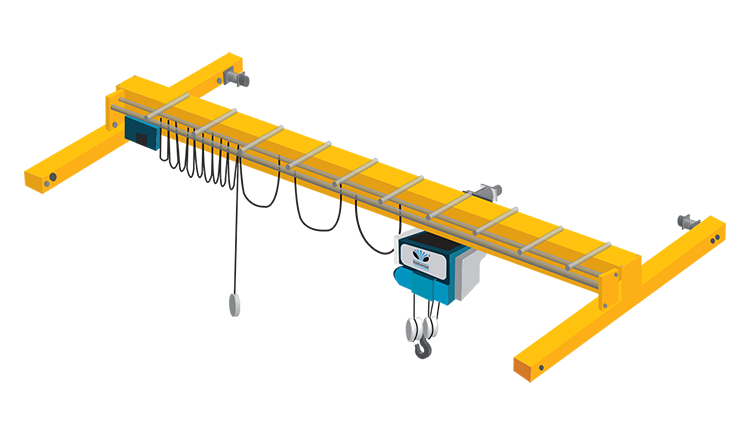

Single Girder overhead traveling cranes designed and manufactured in compliance to IS 807 & IS 3177 for different applications to appropriate class & duty / Hoist machinery designed in compliance to IS 3938. It is provided with high-quality, cost-effective design suitable to customer application.

| Capacity | : 1 MT to 15 MT |

| Span | : 3 M~22.5M |

| Class | : II, III & Heavy Duty |

| Painting | : Primer and finishing paint |

| Colour | : according to your demand. Working Environment |

| Temperature | : -20° to +40° |

Advantages and Features:

- Single Girder Cranes are designed and manufactured in compliance with the duty classification as per IS-3177 & IS-807 for different application.

- Use optimized computer design box type girder as main support girder.

- Best for Low Head Room Space

- All mechanisms are wisely used for Crane Duty applications

- Motor protection class is IP54, F class insulation and equipped with overload protection equipment. (optional)

- Specially designed gearbox for crane, adopts oblique gears, self-lubrication.

- Control stick could be connected with trolley, freely move on main girder separately and can also control the travelling speed according to the different depth of buttons.

- Longer utility life-span and higher working efficiency.

- Travelling speed adopts nonpolar speed adjustment control which result in stable travelling and small sway of crane.

- Easy to overhaul

Installation:

Single Girder EOT Crane 5 MT

Single Girder EOT Crane 5 MT

Single Girder EOT Crane 10 MT

Single Girder EOT Crane 10 MT

SG EOT 3 MT – 28 Mtr

SG EOT 3 MT – 28 Mtr

Applications:

Oil & Gas

Pharmaceutical

Logistics

Food Processing

Chemical

Cement

Packing

Mining

Frequently Asked Questions (FAQ):

A single girder EOT (Electric Overhead Traveling) crane is a type of overhead crane that features a single horizontal beam (girder) for supporting the bridge and trolley.

- Small to medium-sized manufacturing facilities

- Warehouses

- Workshops

- Maintenance facilities

- Assembly lines

- Cost-effective solution for light to moderate lifting applications

- Easy installation and maintenance

- Compact design suitable for limited headroom spaces/li>

- Efficient material handling within confined areas

- Required lifting capacity

- Span and lifting height

- Duty cycle and operating conditions

- Available space for installation

- Power supply and control options

- Safety features and compliance with regulations

- Regular inspection of critical components

- Lubrication of moving parts

- Monitoring of electrical systems

- Prompt repair of any damages or faults

- Training for operators on safe usage and maintenance procedures

Yes, single girder EOT cranes can be tailored to specific requirements regarding capacity, span, lifting height, and operational features.

- Operator training and certification

- Overload protection systems

- Emergency stop buttons

- Limit switches to prevent collisions and over-travel

- Regular inspection and maintenance routines

- Clear communication between operators and ground personnel.